Frictional Resistance and Required Thrust

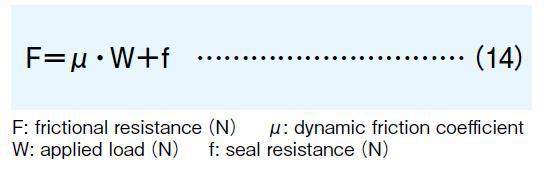

The static friction of a linear system is extremely low. Since the difference between the static and dynamic friction is marginal, stable motion can be achieved from low to high speed. The frictional resistance (required thrust) can be obtained from the load and the seal resistance unique to each type of system using the following equation:

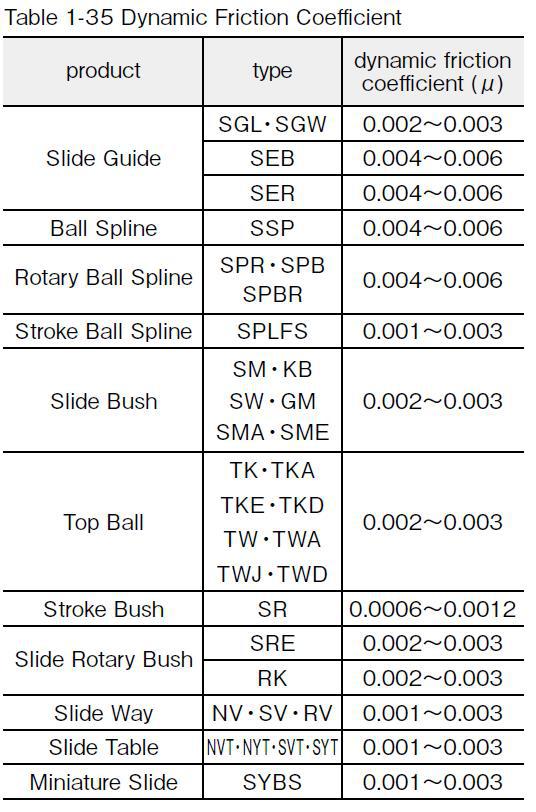

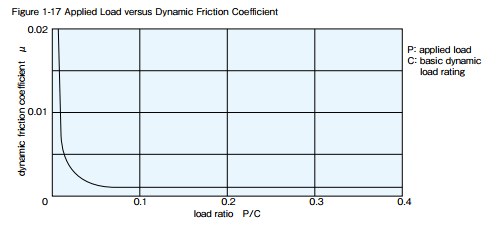

The dynamic friction coefficient varies with the applied load, preload, viscosity of the lubricant, and other factors. However, the values given in Table 1-35 are used for the normal loading condition (20% of basic dynamic load rating) without any preload. The seal resistance depends on the seal-lip condition as well as the condition of the lubricant, however, it does not change proportionally with the applied load, which is commonly expressed by a constant value of 2N to 5N.

|

Dynamic Friction Coefficient

|

Applied Load versus Dynamic Friction Coefficient

|

|

|