How Basic Ball Spline Technologies Affect Performance

Before you specify a rotary ball spline, ask the question, “Should the rotary spline nut be riding on angular contact ball bearings or crossed roller bearings?” After ascertaining your application’s requirements – stroke length; velocity; applied load; mounting space; duty cycle; required life; dimensions; installation direction; environment and accuracy – you’re ready to factor in the

pros and cons of the two technologies.

If you are considering a rotary ball spline, you know that in addition to a ball spline’s forte – transference of torque – the rotary ball spline adds a nut that rotates on the ball spline shaft making the unit capable of simultaneous linear and rotary motion with sub-millimeter accuracy. These linear and rotational capabilities would seem perfectly suited to a multitude of automation applications. However, design considerations make choosing which kind of rotary ball spline critical, i.e., whether the rotational nut rides on angular contact ball bearings or crossed roller bearings.

Initially, however, since the performance of a rotary ball spline is also affected by different ball spline technologies, we’ll take a quick look at basic ball spline technologies, first.

Ball Spline Construction

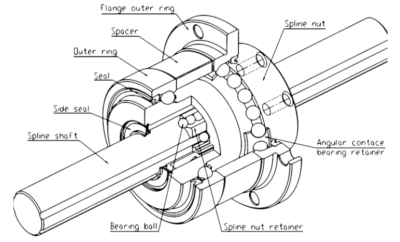

A ball spline is constructed with 3 basic components: a grooved shaft, a spline nut, and ball bearings. Unlike ball bushings, the ball spline nut rides on a grooved shaft, which prevents the nut from rotating on the shaft. This allows transfer of torque through a shaft to a nut or vise versa. However, a typical application requires the shaft or the nut to be mounted to a fixed structure. When the shaft needs to be fixed, ends of the shaft can be turned down to accommodate the mounting of radial bearings which will support rotation, however when the nut needs to be fixed, the radial bearing must be mounted on the outer diameter of the nut which can make overall assembly bulky and the nut is not as easily modified to accommodate various bearing sizes.

This is where the rotary ball spline becomes efficient and economical. Because the rotary ballspline already has a radial support bearing built into the ball spline nut, there is no need for a user to find, source, and integrate one. Moreover, the overall dimension of the rotary ball spline nut is much more compact than a standard ball spline nut with an added radial support bearing.

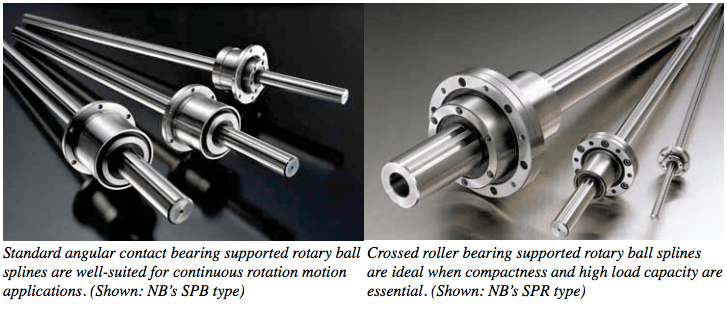

NB’s SPB standard angular contact bearing supported rotary ball spline showing ball elements

in the rotary nut.

The Importance Of Preload

When a force causes rotation of either the shaft or spline nut (not the rotary nut), the nut and shaft will rotate together because the nut’s ball bearings are secured by the grooves. Angular backlash occurs when the space between the spline nut and shaft allows a little bit of wiggle room, i.e. the balls are not preloaded. When you try to rotate one or the other, if it is not preloaded, you can have a little slack and that tiny space allows the angular backlash. So when you rotate the load, you rotate the shaft and the nut doesn’t immediately follow or the nut moves over a little because there is a slight clearance. That is the angular backlash.

The higher the preload grade, the tighter the balls are in the grooves and the more friction is produced. It is important to select the appropriate preload grade for the application to maximize the ball spline product life, rigidity and accuracy, and maintain smooth movement. There are standard preloads offered by manufacturers or you can request a custom preload.

Preload can also increase the rigidity of the spline by reducing assembly deformation under application load. Because the initial deformation amount is much greater on steel, pre-deforming the components by insertion of larger diameter balls can reduce the amount of deformation when the spline assembly is loaded for an application. As a result the assembly will be more rigid and more accurate.

Maximizing Torque

The number of grooves on the spline shaft as well as the number of points of ball contact in the grooves is the characteristic that dictates torque ratings. Ball splines that have shafts with 4 grooves will have higher torque ratings than those with 3 grooves. Likewise, gothic arch shaped grooves with a 4-point contact design provide a higher rating than circular arch shaped grooves, which have two points of contact. The gothic arch eliminates any clearance that could lead to deflection and is, therefore, best suited for applications requiring maximum precision. Four-point contact also increases the load capacity and rigidity so that it can handle a greater load and torque. So with a 4-groove spline and 4-point ball contact, the total contact per spline shaft is sixteen whereas with three grooves and two contacts per groove there would be only twelve points of contact. Though different ball splines might be exactly the same size, they can have very different torque ratings.

Shaft Characteristics That Affect Accuracy

Increasing how symmetrical the spline shaft is can increase the maximum rotational speed and stability of the spline shaft through reduced vibration.

Spline shafts vary as to whether they are precision-ground, ground or drawn steel bar. They also vary as to the grade of the base material. Manufacturers rank shafts by characteristics such as the tolerance of ground shafts, perpendicularity to the end face, concentricity of the partmounting section in relation to the support section, as well as the material grade.

Controlling machining of all the shaft grooves so they are linear all the way through in high accuracies is very difficult. Non-ground (drawn) spline shafts are, naturally, of lower accuracy. Generally, manufacturers present 3 accuracy ratings, Precision (meaning their highest precision) High (meaning their standard grade – usually a stock item) and Normal or Commercial (often a non-ground shaft). However, one manufacturer’s top grade can be another’s standard grade. Comparing accuracy grades comes down to comparing measures of the above-mentioned ranking characteristics – shaft diameter tolerance, straightness, perpendicularity and concentricity.

If a lesser degree of accuracy is acceptable because the primary concern is torque transfer, linear transfer, rotational motion or length, then drawn, non-ground spline shafts may be the best choice. Some drawn shafts can use the same nuts as ground spline, but load capacity is reduced because the nut is traveling in a non-ground raceway groove. However, they are less expensive and can be as long as five meters, making them appropriate for material transfer and handling applications.

What Is A ‘Crossed Roller Bearing’ Rotary Spline Nut?

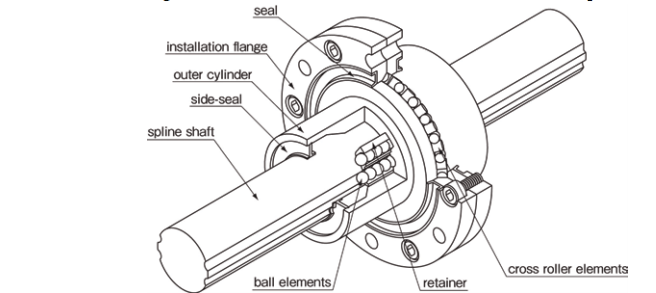

Crossed roller bearings work similarly to ball bearings, except that the bearings housed within the rotary nut are cylinder-shaped instead of ball shaped. The rollers crisscross each other at a 90° angle and move between “V” grooved bearing ways or grooves ground into the spline nut outer diameter and rotary flange attached on the nut.

Crossed roller bearings offer a line of contact versus a ball bearing’s points of contact, thereby creating a broader contact surface that can carry a heavier load. This provides more rigidity, less deformation and thus more accuracy compared to the point contact of balls. Because of this, crossed-roller bearings are the most accurate form of mechanical motion component.

As rotary support bearings, both angular contact bearings, which ride on balls, and crossed roller bearings can support both axial load and radial load as both types of loading or combined loading can be expected depending on ball spline applications. An angular contact bearing achieves this with two rows of balls whereas a crossed roller bearing can do this in a single row, but with some disadvantages such as speed and wear issue as described below.

Dimensions

When comparing dimensions, one is immediately struck by the difference in size between a Rotary Ball Spline whose rotary support bearing rides on crossed roller bearings as opposed to an RBS whose rotary support bearing rides on ball bearings, i.e. an angular contact bearing. On the spline shaft, the spline nuts are basically the same. In each case, they ride on ball bearings. The RBS whose rotary support bearing rides on crossed roller bearings is much more compact. The reason the crossed roller bearing supported rotary ball spline takes up so much less space is that the rotary nut and spline nut is one unit. The crossed rollers are directly attached to the spline nut’s outer cylinder. In addition, the crossed roller rotary support bearing is thinner.

Compactness

The crossed roller type is compact. It has a relatively high load capacity in terms of the size of the crossed roller section. It’s ideal when you need to keep something compact and support a high load for an application that doesn’t require continuous rotation. Since an angular contact type is larger, the rotational section is larger, with the overall spline dimensions being larger than the crossed roller type. Its large footprint reduces the compactness of the overall application.

Accuracy and Deflection

Crossed rollers provide a larger contact area than ball bearings, reducing elastic deformation. Because of this greater stiffness, crossed rollers provide consistently precise movement. There is a direct correlation between the contact area of the crossed rollers and load capacity. Load capacity can be increased greatly by roller-to-raceway contact. Balls, typically, make contact at two to four points.

Endurance

However, for applications that continuously rotate, crossed rollers wear out more quickly than ball bearings because more of their contact area is in use. For example, an angular contact type is a better choice for driving the spindle drive shaft of a grinding machine, a conveyor belt or a wire winder. Whereas, crossed rollers are highly desirable when the attached gripper rotates back and forth, such as moving a half or quarter rotation when changing the angle of an item.

Rotational Speed

In a rotational speed comparison, the angular contact type is more advantageous than the crossed roller type. Comparing the two types at a standard 16mm (the diameter of the spline) size, the crossed roller type nut is capable of 1,080 rpm versus the maximum rotational speed for an angular contact type nut, which is 4,000 rpm.

Retrofitting

Since crossed roller rotary nut technology is newer, most existing applications already use the angular contact bearing supported ball spline. That makes changing to the newer technology expensive since it’s not the same size – it’s more compact. However, most angular contact bearing supported ball splines are interchangeable, size-wise. Though outer dimensions of interchangeable rotary ball splines may be the same, there are design advantages to consider such as the number of grooves on the spline, the points of ball contact within the grooves and shaft rigidity.