In linear motion NB provides a numerous and diverse range of products from basic machine parts to semiconductor equipment and specialized machines. Furthermore, we also provide Spindle products that correspond perfectly to the individual requirements of our various customers. NB Splindle products can be provided as a unit including assembling work as well as machining parts.

Spindles

Product Description

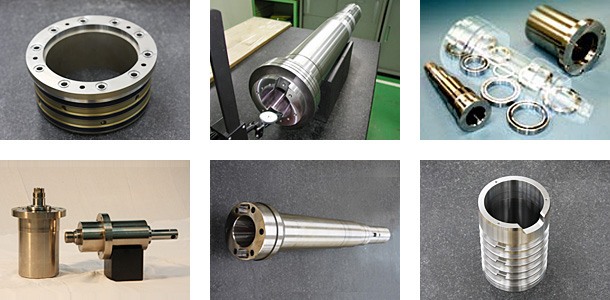

NB spindle shafts complement an industry-leading line of bearings, bushings and related products. We offer engineering, manufacturing and overhaul of spindle units to provide a complete solution for general machinery, semiconductor and a diverse range of other applications. ISO 9001- and ISO 14001-registered facilities allow us to deliver outstanding quality control, even for high volume orders.

Keep reading to learn more about our spindle shaft manufacturing capabilities or contact our office directly to request a quote for your project.

Key Benefits At-a-Glance

NB’s experience in spindle shaft manufacturing and other precision machining dates back to 1939. In that time, we’ve developed a reputation for unsurpassed quality and innovation in everything we do. When you contact us for any spindle shaft engineering project, you are working with a company that’s dedicated to providing:

Flexible manufacturing options

including bearing case and spindle base design, complete unit engineering and overhauling of worn components

Precision machining capabilities

in our state-of-the-art, climate-controlled facilities designed to meet exceptionally high requirements for tolerance and overall quality control

Innovative surface treatments

including hard chroming and ceramic coatings for new components, as well as re-plating and grinding worn units to restore them

Our spindle manufacturing capabilities include BT, BBT, HSK inner tapers, gauge and bearing matching, thread grinding and more. We work with a wide range of standard materials, including high-carbon chromium bearing steel, Martensitic stainless steel, steel alloys and carbon steel for tools and machinery, aluminum chrome molybdenum steel and more.

Our facilities are equipped with CNC lathes, boring and milling machines, vertical machining centers, internal grinding machines and other machine tools. To discuss your specific requirements with one of our engineers, contact the NB office today by phone or email.

Total Manufacturing Solutions

NB is committed to providing total manufacturing solutions for clients in any industry. We’ll work with you every step of the way to deliver a product that meets your needs, offers excellent value for your budget and is turned around within a reasonable timeframe.

Upon receiving your drawings, we’ll review what’s required, order the necessary materials and develop a comprehensive plan for completing the project. From there, the spindle shaft production process involves multiple steps of turning, heat treatment, grinding and milling. It concludes with a final inspection to confirm we completed all work to the requested specifications.

Our internal quality management processes ensure we complete orders of any size on time, on budget and to the highest standards of accuracy possible. Highly skilled technicians use sophisticated 3D measuring tools and work in a climate-controlled environment to deliver the best possible results for our clients. We ship the final product with a complete inspection sheet confirming your order meets your specifications.

Spindle

As a linear bearings manufacturer, NB is serving a variety of customers in many industries such as general machinery, semiconductor equipment, special purpose machines.

The NB SPINDLE is a further contribution to the industry. From parts to the spindle unit NB conducts integrated production through total manufacturing.

Please contact us for any requirement.

NB SPINDLE is backed by expertise gained from decades of experience in high accuracy machining.

NB keeps supplying high quality products through skilled labor with time-nurtured skills, time-tested production process and technology, in addition to a help of the state-of-the art technology and equipment.

We have a belief that high processing technology is the key to customer-satisfaction.

| Outer Surface Machining | Range |

|---|---|

| Maximum diameter | 650mm |

| Maximum length | 6000mm |

| Surface roughness | Ra0.4 |

| Straightness | customer specification |

| Concentricity | customer specification |

| Perpendicularity | customer specification |

| Cylindricity | customer specification |

| Deep Hole Machining | ||

|---|---|---|

| Hole diameter | Maximum length | |

| one side | through hole | |

| Φ2~2.5mm | 200 | 400 |

| Φ3~3.5mm | 300 | 600 |

| Φ4~8mm | 500 | 1000 |

| Φ9~10mm | 750 | 1500 |

| Φ10~32mm | 850 | 1700 |

| Φ30~80mm | 2000 | 4000 |

| Internal Surface Grinding | straight or tapered internal portion |

| Screw Grinding | triangular and trapezoidal screws |

| Matched parts | special nuts to match a given shaft, tapered portion of inner or outer diameter to match a given shaft or bearing |

| General machining | center tapping, step machining, V-groove machining, screw machining, plate-groove machining, key-groove machining, flat surface machining, spot hardening |

| Surface Treatment | industrial chrome plating, low temperature black chrome treatment, other customer request |

| Thermal-spraying Ceramic-coating (best-suitable for parts that require wear and corrosion resistance) | |

|---|---|

| (1) standard material high carbon chromium bearing steel (SUJ2) chrome molybdenum steel (SCM415, 435) carbon steel for machinery (S45C) martensite stainless steel (equivalent to SUS440C ) austenite stainless steel (SUS303, 304) steel alloy for tools (SKS3, SK4) aluminum chrome molybdenum steel (SACM645) |

(2) standard ceramic for thermal-spraying main component: TiO2 titanium dioxide specific gravity: 4.7 hardness: 58HRC or more maximum temperature: 540℃ color: black fine surface finish by grinding |

In response to customer requirements, NB provides total manufacturing from the receipt of drawing to final inspection. Total manufacturing includes process planning, material procurement, turning, heat-treatment, milling, surface treatment and grinding.

- Drawing

- NC Lathe

- BTA Boring Machine

- CNC Internal Grinding Machine

Process Chart (standard example)

Accuracy / Quality Control

Inspection room is set at 22+/-1℃ to ensure accurate inspection.

High Precision Machining and Inspection Technology lead to the Final Inspection.

To ensure accuracy it is necessary to have skilled operators and inspectors at the same time. Skilled inspectors perform reliable measuring skills on the finished products.

Temperature Controlled Manufacturing Facility

Quality is assured with 3-D measuring machine, shape measuring machine, circularity measuring machine, etc. in the constant temperature room.

- Temperature is strictly monitored

- Coordinate Measuring Machine

- Circularity Measuring Machine

- Measuring Devices and Gauges

In-house Equipment

In order to answer every requirement from the customer, NB invest in the equipment. Following are a

part of machines at hand.

- CNC Lathe

- Cylindrical Grinding Machine

- CNC Horizontal Boring and Milling Machine

- Cylindrical Grinding Machine

- CNC Horizontal Boring and Milling Machine with Sliding Table

- CNC Vertical Grinding Machine

- Vertical Machining Center

- CNC Internal Grinding Machine

- Balancing Machine

- Precision Internal Grinding Machine

Q & A

Yes, we do volume production. Please contact us.

Standard materials are:

High Carbon Chromium Bearing Steel (SUJ2)

Chrome Molybdenum Steel (SCM415, 435)

Carbon Steel For Machinery (S45C)

Martensite Stainless Steel (equivalent to SUS440C )

Austenite stainless Steel (SUS303, 304)

Steel Alloy For Tools (SKS3, SK4)

Aluminum Chrome Molybdenum Steel (SACM645)

Please contact us for other materials.

Yes, it is. Non-magnetic austenite stainless steel (SUS303, 304, 316) and martensite stainless steel (equivalent to SUS440C ) are examples.

Please contact us for other materials.

We ship the final product with an inspection sheet. Please advise us the necessary inspection items on ordering.

We can handle threading (triangular and trapezoidal screws). We welcome total machining including threading.

Standard Treatments Are:

Industrial Chrome Plating

Electroless Nickel Plating

Black Oxide

Low Temperature Black Chrome Treatment (With Fluoride Coating)

Please contact us for other surface treatments.