La GUÍA LINEAL NB tipo SGW es un sistema de riel de guía lineal de perfil que utiliza el movimiento recirculante de elementos de bolas a lo largo de cuatro filas de ranuras de canal. Su baja altura y amplio perfile la hacen adecuada para aplicaciones de un solo riel.

Guía Lineal – Tipo SGW

Descripción del producto

Usted necesita soluciones de movimiento lineal que cumplan con sus requerimientos específicos. Usted se puede estar enfocando en un aspecto en particular como la precisión, carga máxima, suavidad, limpieza o mantenimiento, o puede estar buscando una combinación de estos y otros aspectos.

En NB, diseñamos nuestras guías lineales de la serie Guía Lineal SGW y rieles para sobrepasar sus necesidades y proveerle la solución óptima para toda situación. Para ofrecerle la más alta calidad y resultados más duraderos, hemos incorporado elementos de bola que aprovechan el movimiento recirculante en nuestros sistemas de riel de guía lineal. Este diseño asegura el movimiento consistente y confiable de sus guías de riel lineales en todo su equipo.

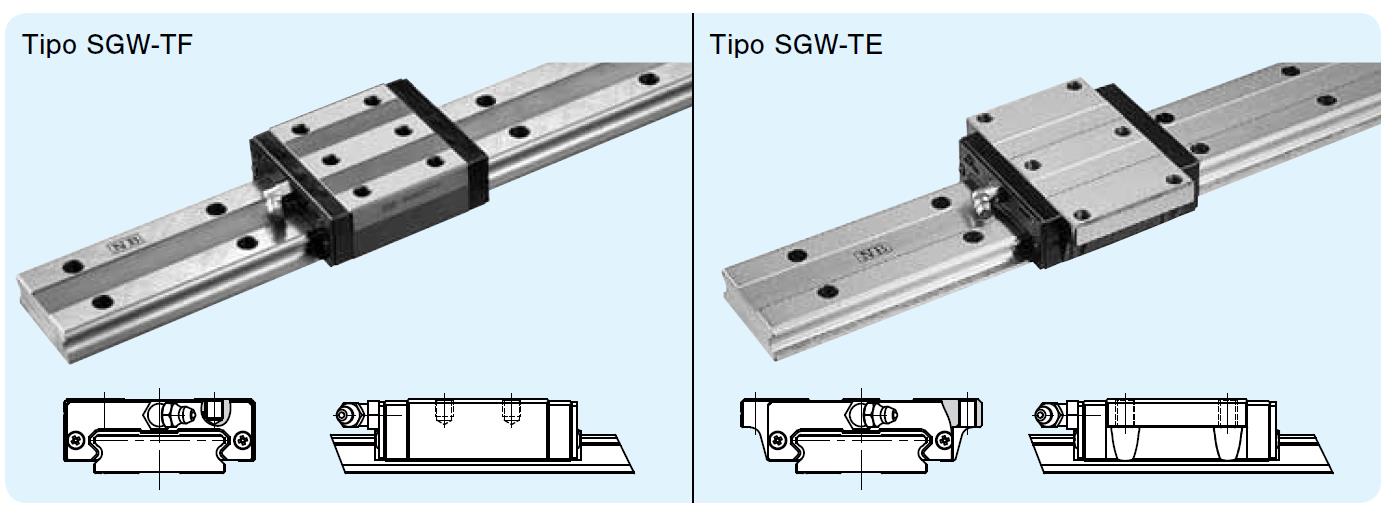

Creamos la serie Guía Lineal SGW de NB para ser flexibles ante todo tipo de aplicaciones. Se incluye dos tipos de montura SGW para cumplir con sus necesidades:

SGW tipo TF

Con una baja altura y superficie estrecha de montado que le permitirán minimizar el tamaño y peso de sus instalaciones.

SGW tipo TE

Con una superficie de montura más ancha para un rango más amplio de posibilidades de montura, a la vez que mantiene un tamaño compacto para aplicaciones de un solo riel.

Empleamos diseño de precisión, materiales de alta calidad y manufactura de avanzada para mantener nuestra posición de líder mundial en soportes lineales a lo largo de nuestro rango completo de productos.

Características de Alto Nivel

Nuestro sistema único de retenedor de bola incluye características que maximizan la precisión y capacidad de nuestros sistemas de riel de guía de movimiento lineal. Elija NB y benefíciese de:

Alta capacidad de carga

Con nuestra alta capacidad de carga, usted puede construir sus máquinas y equipos para adecuarse a sus especificaciones exactas, asegurando una larga vida.

Carga omnidireccional

El ángulo de contacto de 45° de nuestros elementos de bola provee una capacidad de homogénea de carga de arriba a abajo y de lado a lado, proporcionando movimiento extremadamente suave.

Requerimientos de higiene

Cada sistema de riel de guía lineal SGW de NB incluye sellos laterales de polvo. Para las más demandantes necesidades de higiene, podemos incorporar tapas y sellos de polvo adicionales.

Su éxito y satisfacción son nuestra meta principal. Elija NB como su confiable compañero para todas sus necesidades de movimiento lineal, para incrementar la eficiencia de su equipo, mantener la precisión del movimiento lineal y reducir las programaciones de mantenimiento.

Información Detallada

Nuestros clientes vienen de un amplio rango de sectores industriales, pero todos ustedes tienen una cosa en común: Necesitan confianza y precisión en sus rieles lineales y soportes. El elegir de nuestro catálogo de Guías Lineales SGW de NB, le añade flexibilidad a su diseño de máquinas, al igual que incrementa la eficiencia y longevidad gracias a las tolerancias de precisión y la lubricación integrada.

Hacemos que sea fácil el integrar los sistemas de riel de guía lineal NB. Descargue nuestros detallados archivos CAD 2D y 3D hoy mismo para que pueda diseñar su equipo, o contáctenos para más información..

ESTRUCTURA Y VENTAJAS

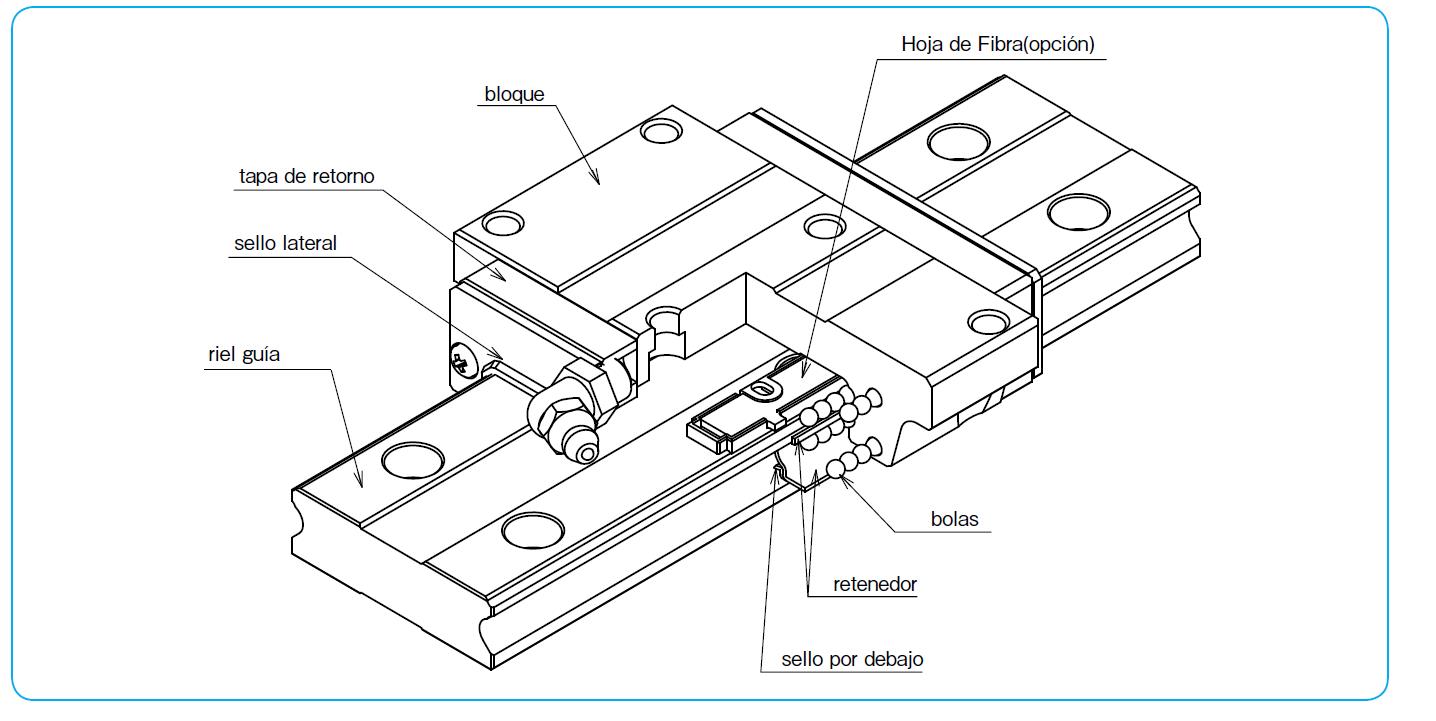

El tipo SGW de GUÍA LINEAL consiste de un riel con cuatro ranuras de canal elaboradas con alta precisión y un ensamble de bloque. El ensamble de bloque consiste del cuerpo principal, elementos de bola, retenedores, y tapas de retorno.

Alta Capacidad de Carga y Larga Vida

Las ranuras de canal son maquinadas para un radio cercano al de los elementos de bola. El área mayor de contacto resulta en una capacidad alta de carga y una larga vida de recorrido.

Especificación Anti-corrosión

El ensamblaje de bloque y el riel pueden ser tratados con cromo negro a bajas temperaturas para incrementar la resistencia a la corrosión. Este tratamiento es estandarizado con el símbolo «LB», y es adecuado para uso en aplicaciones de cuarto limpio.

Alto Momento Permisible

Su amplio perfil le permite sostener cargas de alto momento, haciéndola adecuada para aplicaciones de un solo riel.

Prevención de Polvo

Se proporcionan sellos laterales como un estándar. Para mejorar las características de prevención de polvo, tenemos disponibles bajo sellos y tapas de montado de riel.

Capacidad de Carga Omni-Direccional

Los elementos de bola están posicionados en un ángulo de contacto de 45° para que la capacidad de carga sea igual en las cuatro direcciones (arriba, abajo, derecha e izquierda).

Extensión del Período de Relubricación

mediante Hoja de Fibra

Una Hoja de Fibra que contiene lubricante es incorporada en el bloque para proveer la cantidad adecuada de lubricante a las ranuras de canal, lo cual puede extender significativamente los intervalos de reabastecimiento de lubricante.

Movimiento Suave

El gran número de elementos efectivos de bola producen un movimiento de rodado suave.

Estructura de la GUÍA LINEAL tipo SGW

Tipos

Dependiendo del espacio y método de montaje deseado, dos tipos de bloques SGW están disponibles.